A little more than six months ago we published a blog post that gave an overview of ordering custom-made products (the article titled “More than the products in the online shop” can be found here). This post gives examples of some of the products you can order from us in addition to the products available in our online shop. Having recently fulfilled several interesting special orders we hereby encourage you to contact us about any plans you might have – our experienced specialists will definitely find a suitable solution for you.

Below we will give you an overview of a unique project which took us less than a month to complete – starting from a call from the customer and until the ordered detail was installed. If you too are considering ordering a detail made of Estonian limestone (Reval) or dolomite (Kaarma, Orgita, and Selgase), but you are not certain whether the plan can be carried out, don’t hesitate to get in touch and we can discuss the matter in more detail.

A decorative stone for an earth cellar

Stage 1: first contact and initial data

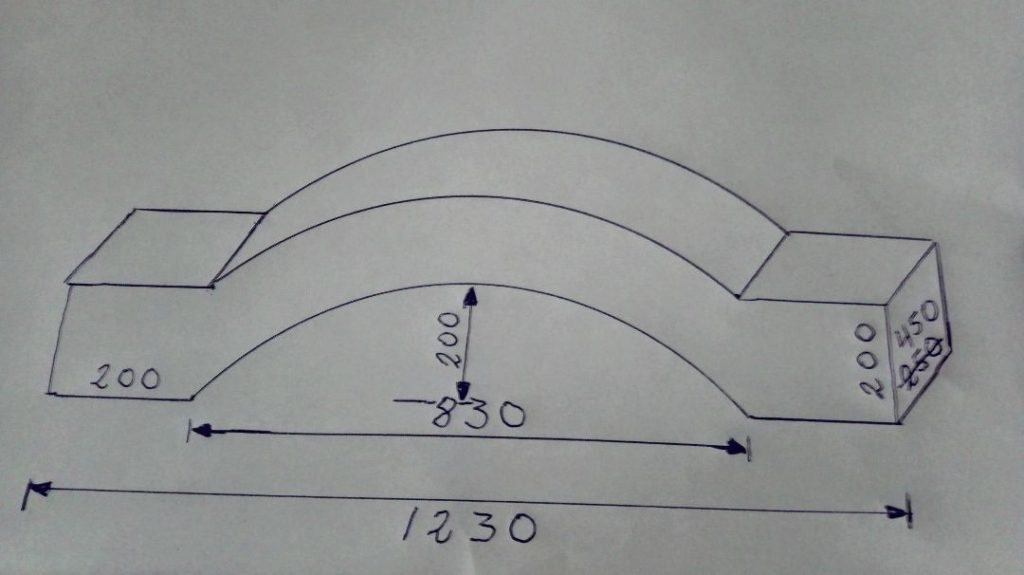

One day in mid-September when the calendrical autumn was not here yet, we received a call from a builder who wished to place an order for an arch over an earth cellar’s door. After the initial consultations, we got some important additional information from the builder: a drawing (a hand-drawn sketch which was completely sufficient in this case – fulfilling a project will certainly not be hampered by a missing professional drawing!) and a photo of the situation at the object. All that in order to be able to think along in the best possible way.

Stage 2: selecting the material and specifying the details

At first, the client chose our Orgita dolomite for the project. But after getting some more information about our different materials we together decided to use Kaarma dolomite (also known as Saaremaa marble). This was mainly because unlike Orgita dolomite the Kaarma dolomite does not have yellowish tones and that Kaarma stone gives a much more rustic look.

We have a quick recommendation for everyone who is planning on ordering custom-made details. In case of special items, we recommend choosing one of our dolomites – either Kaarma, Orgita, or Selgase. Limestone Reval is not suitable for producing several types of details as the raw blocks coming out of the quarry are quite thin and this does not enable producing many types of products. In addition to that, the dolomites we mentioned are also weather-resistant (in the case of limestone Reval all installation methods do not guarantee the same level of weather resistance).

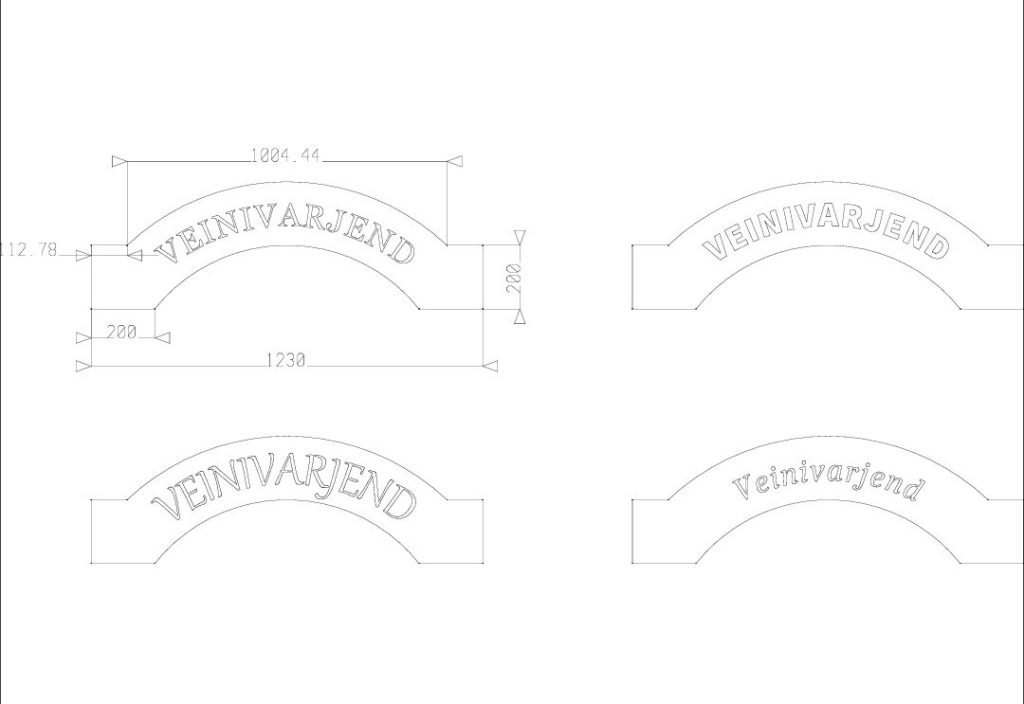

After the material was selected, we were able to calculate the cost. As there was some time between submitting the order and giving the final touches in the production process, it was possible to make an addition to the project – the text “Veinivarjend” (“Wine shelter”) was added to the stone.

Stage 3: collaboration with the CNC operator

The next stage of production included the CNC operator. The operator added the information from the drawing to the software and also proposed to the client some samples with different fonts for the sign. CNC means operating a device or a machine tool based on the data entered into some software – the operator programs the machine, and the machine processes the material according to the data entered. In the case of this project, it meant cutting the desired shape from a block of stone. This is quite time-consuming especially when the projects are more complicated. The whole CNC process for the “Wine shelter” project took nearly a whole working day (together with entering the data).

However, if the order includes several similar details, the production time per detail is significantly lower. This of course has positive effects on the unit price.

Stage 4: the final touch

After the CNC process, the custom-made product will literally be given the final touch. It will be handed over to workers whose role it is to hone the detail. In this case, the product’s front side and lower part were honed by hand. When the final touch has been applied, the product moves on to the packing area – the detail will be put on a pallet, some supports are added (which enable it to be delivered securely) and the goods will be handed over to the delivery company.

In this case, the customer received the product three and a half weeks after the first phone call. The customer was very satisfied with our work and sent us several photos (some of which have been published here).

Custom-made details will be produced quickly

As you can see, the whole project went smoothly and it took only a few weeks to receive the finished product. Even if you only have an initial idea for your project, feel free to contact us (our contact information can be found here). We can move on based on your initial idea and some general sketches. We can work out how to produce the required details in the best possible way and which of our natural stones we should use for that.

Several of the standard products available from our online shop can to some extent be altered and custom-made. For example – in the case of window sills and countertops we have applied some limitations arising from the production process. But in some cases, it is also possible to produce larger details or products with different shapes. Therefore, we recommend you to contact us as soon as possible.